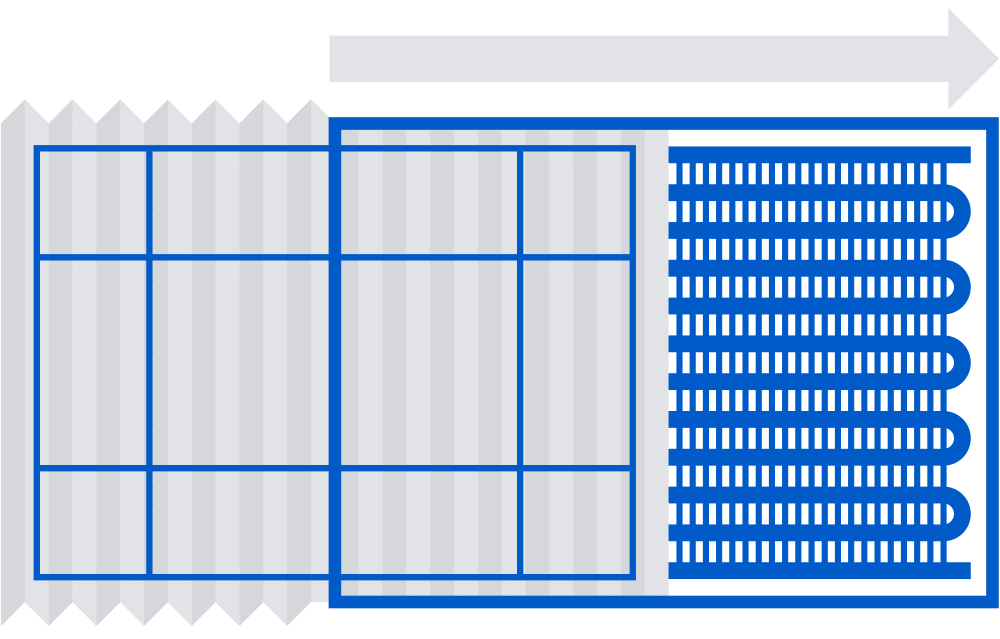

Box filters are 1/2 inch shorter than needed on each side, which results in inadequate coverage due to unavoidable gaps.

Customized. Compact.

Cardboard-free.

PleatLink® Filtration System.

PleatLink® minimizes or eliminates air bypass allowing evaporator coils to stay cleaner longer.

BFC Solutions patented, cardboard-free PleatLink® Filtration System combines continuous MERV 8 or MERV 13 media with a reusable metal frame. The complete system runs the full length of the HVAC unit’s filter track, which greatly reduces air bypass and protects coils from unfiltered particles.

Conventional box filter vs PleatLink® Filtration System.

Standard box filters are designed as a ½ inch shorter than needed on each side, which leads to inadequate coverage due to gaps between and around edges. The gaps allow for air bypass and cause tiger striping on the coils.

The PleatLink® filter media extends beyond the top and bottom of the reusable metal filter frame by 1 inch on each end, creating a gasket-like seal. This reduces air bypass and captures more contaminants than traditional box filters.

The pluses of PleatLink®

- Keeps coils cleaner longer

- Prevents evaporator coil tiger striping

- Protects downstream assets from unfiltered particles

- Improves energy efficiency

- Extends asset life

- Reduces impact of long-term air bypass

Air bypass from traditional cardboard box filters.

It isn’t a maintenance issue — it’s a design flaw.

These gaps allow unfiltered air to ‘bypass’ the filters and reach system mechanicals, causing unnecessary wear and tear.

Causes tiger striping and dirt to build up on evaporator coils, leading to inefficiency and increased energy consumption.

Patented by design. Proven in practice.

Here’s what it means for you.

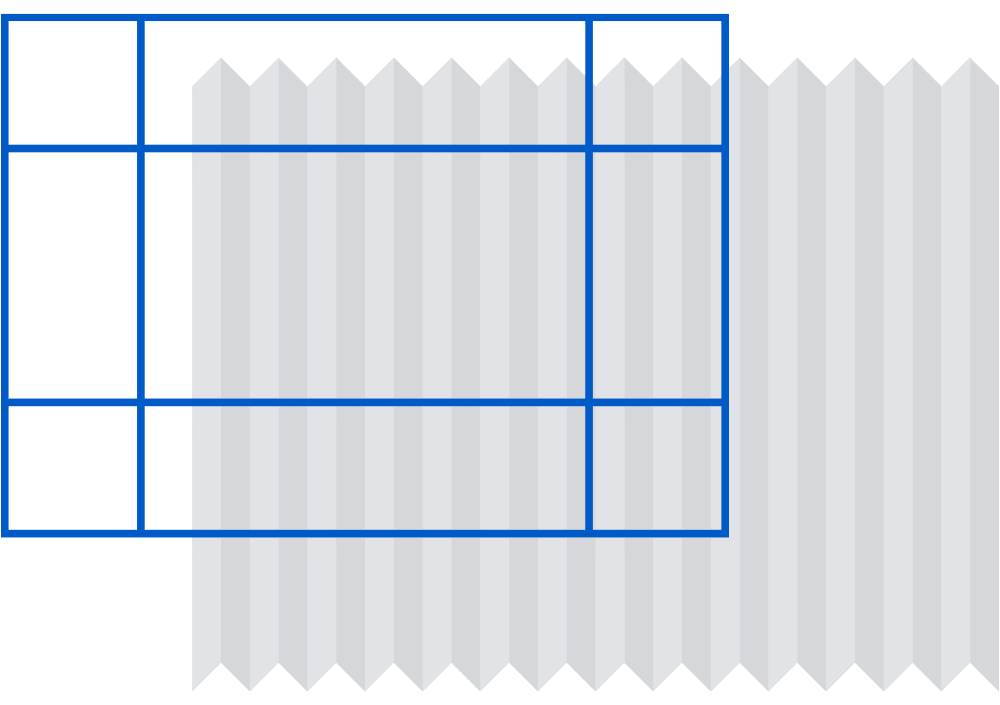

Filters are purpose fit for each unit to protect evaporator coils.

Customized: Purpose fit to the unit.

PleatLink® is engineered to integrate seamlessly with commercial HVAC equipment. Each metal frame is customized to the size of the unit’s filter track, then paired with a continuous piece of PleatLink® filter media sized to fit the frame—creating a single, uninterrupted filtration surface.

The result is a fully sealed frame-and-media system that fills the entire filter track of the specified unit and eliminates air bypass.

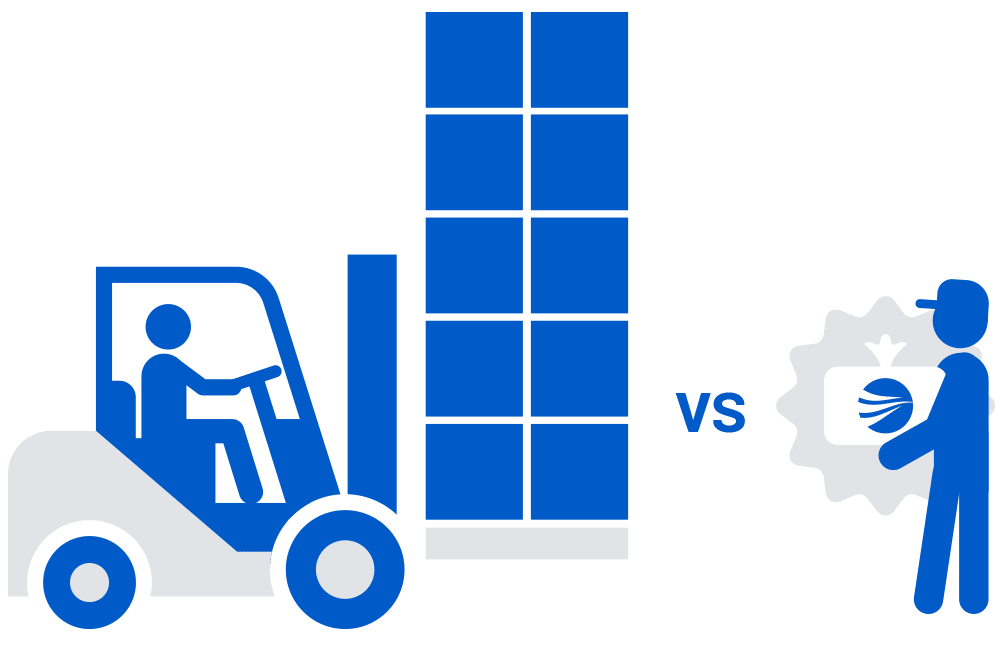

Our technicians can load an entire week's service route on their van.

Compact: Functional design.

Compared to conventional box filters, PleatLink®’s patented design allows for denser packing and ships at a 20:1 volume ratio—dramatically reducing freight requirements and transportation-related emissions by up to 67%.

That efficiency extends beyond shipping. Fewer, denser deliveries mean reduced fuel consumption in the field, with weekly inventory pickups replacing daily runs.

Saves trees, reduces landfill waste and supports ESG goals.

Cardboard-free: A more sustainable design.

PleatLink® uses a durable, reusable metal frame that eliminates the need to discard cardboard with every filter change—delivering long-term cost savings and a smaller environmental footprint.

Unlike cardboard box filters that can break down in high moisture, humidity, or temperature extremes, the PleatLink® metal frame maintains its structural integrity and protects filtration performance over time.

PleatLink® MERV ratings tested and verified by Blue Heaven Technologies according to ASHRAE standards.